Transformer Oil is used for the insulation and cooling of the transformer. It is a highly refined mineral oil that is stable at high temperatures and has excellent electrical insulating properties. Inside the transformer, it works like liquid insulation, helping with reduced clearances, and then for cooling and carrying heat from the windings and dissipating it through the tank body and Radiators.

Transformer oil is an excellent Insulating Material. It provides Insulation between transformer body and windings. The oil is circulated continuously by natural circulation or forced circulation methods so that releases its temperature which is absorbed from windings to the atmosphere.

Compared to dry type Transformers, the Oil type provides efficient cooling but the cost of a transformer, as well as maintenance charges, are high. Usually high rating MVA transformers preferably oil type.

The oil should be perfectly free from moisture as it will reduce the insulation strength considerably. The insulation property is further reduced due to the formation of sludge which is an oxidation product and its formation is accelerated by the contact of oil with air and temperature.

Transformer Oil Tin

Sludge is also formed due to the presence of acids and alcohols. To minimize oxidation, the oil should be exposed to air at the minimum time possible. The sludge formation reduces heat transfer, blocks the ducts, and increases the operating temperature. To prevent moisture from entering the oil, the whole apparatus is made airtight and calcium chloride silica gel filters are used. Para oxidiphenylantine having a melting point of 65oC is used as an admixture to slow down the aging of oils.

Transformer oil is used in switchgear, and power factor capacitors also.

Properties of Transformer Oil:

- Its dielectric strength is 40kv/mm/min

- Its flash point is 160oC

- Sludge value percentage is 1.2

- Its specific gravity is 0.88

- Its dielectric constant is 22.

- Its pour point is -40 oC

In case of heavy faults, the oil temperature increases suddenly to high values. In this case, it should not lose its properties to avoid flashover.

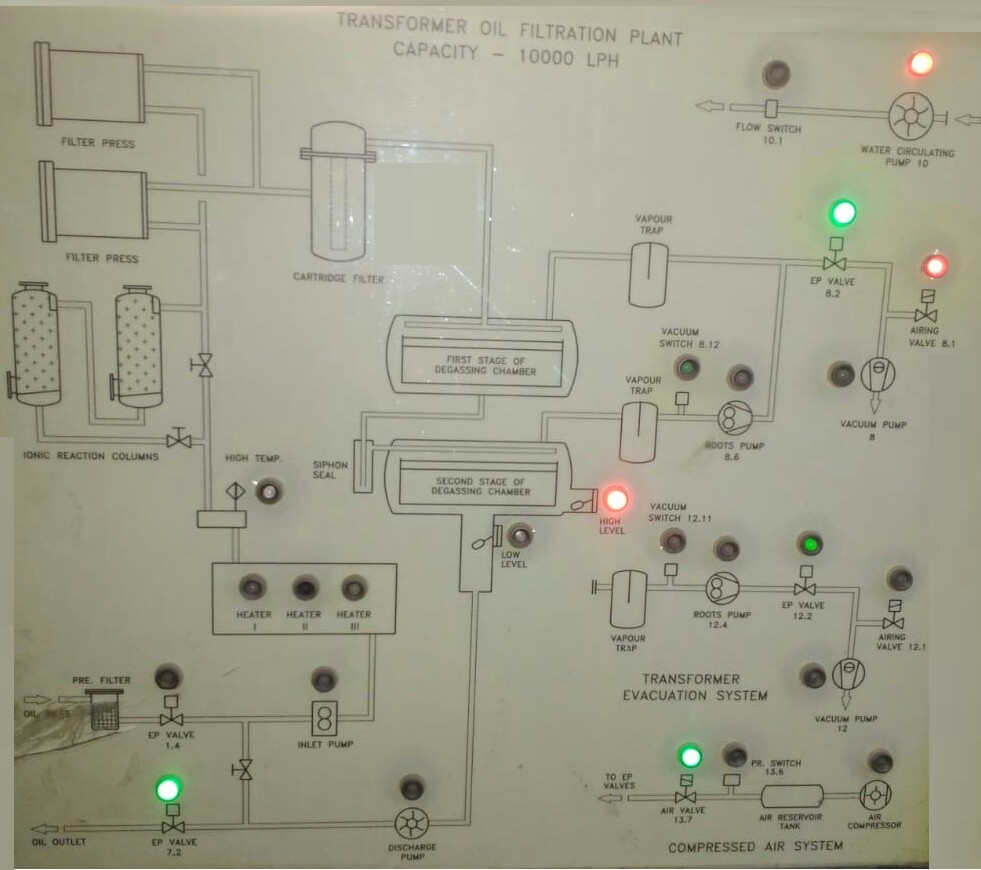

Transformer Oil Filtration:

Whenever oil lost its properties it needs to be filtered. Replacement of oil is not necessary and is not recommended due to its heavy cost. The filtration process is done until the desired properties of the oil are achieved. Oil Break Down Analysis BDA test is frequently conducted while doing filtration. The entire process usually takes 5-8 hours depending on the size of the transformer. Before doing oil filtration the transformer load has to transfer to other transformers otherwise shutdown is needed.

Being a mineral oil, even fresh oil has a certain level of acidity, which when it comes in contact with the air, reacts, creating sludge. At higher temperatures, the activity is faster. Secondly, being mineral oil, it has a tendency to absorb moisture, which in turn reduces the dielectric strength of transformer oil.

The most important job of filtration is

- To improve the Insulation Resistance of the Transformer oil.

- To remove moisture, solid contamination or sludge& gases.

- Filtering process can reduce the acidity of oil to a great extent, thereby improving viscosity, specific resistivity, ageing characteristics, etc., hence extending the life-span of the oil.

![High Impedance Restricted Earth Fault Protection: [64H]](https://electengmaterials.com/wp-content/uploads/2022/02/REF-150x150.png)